Fuse core

LEMER Foundry

Fuse Core:

Metal fuse cores based on low melting alloys enable to make hollow composite parts with very precise tolerances.

LEMER Foundry produces metal cores in its workshops by moulding. This metal core is then coated with a composite (filament winding, RTM, etc.) After a temperature-mounted cycle, the composite material is glazed and the metal core melts. The alloy is recovered to produce new nuclei in small, medium or large series.

Technical specificities:

A wide range of fusible alloys is available according to your requirements from 20°C to 380°C (Vitrification temperature)

These fused metal cores are made with a low melting point alloy: eutectic, single-phase, binary or ternary alloy.

With our DSC (Differential Scanning Calorimetry) thermal analyzer, we guarantee the melting point of these fused metal cores by checking our melting baths.

Areas of Application:

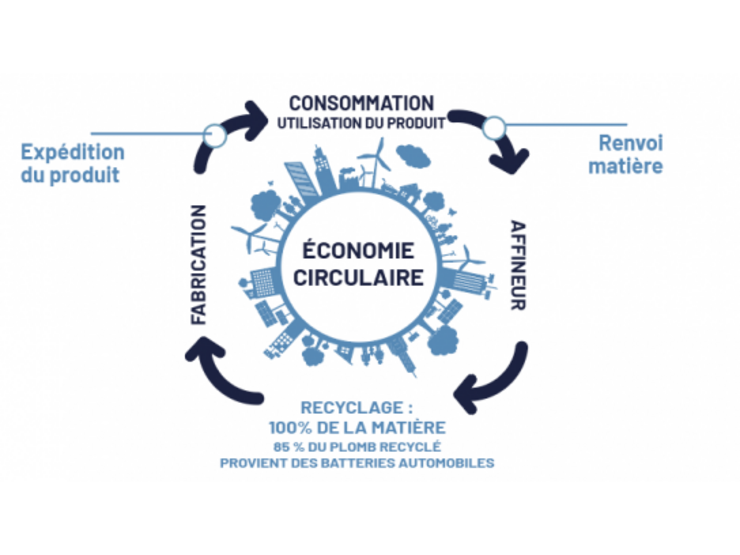

LEMER foundry now supports the development of the manufacture of composite parts by proposing an innovative and environmentally friendly process.

The fuse core is used for the manufacture of hollow parts in the field of aeronautics, automotive, sports competition and aerospace.

This technology increases the performance of your systems by decreasing mass and increasing resistance.

This 100% recyclable process reduces waste and mineral resources. After use, the alloy is recycled, controlled and reintegrated into the material cycle to manufacture new fuse cores by LEMER foundry.